Interlocking

Interlocking is a crucial component in any rail depot, where a momentary lapse of concentration or small error of judgment can have dire consequences.

Interlocking solutions are vital for protecting both personnel and equipment in rail maintenance facilities. They prevent unauthorised train movements or access to high-risk areas and ensure that safety standards are upheld.

Zonegreen solutions apply the concept of interlocking to create increasingly sophisticated systems that can potentially prevent personal injury or costly damage.

Zonegreen Electronic Interlocking Solution (EIS)

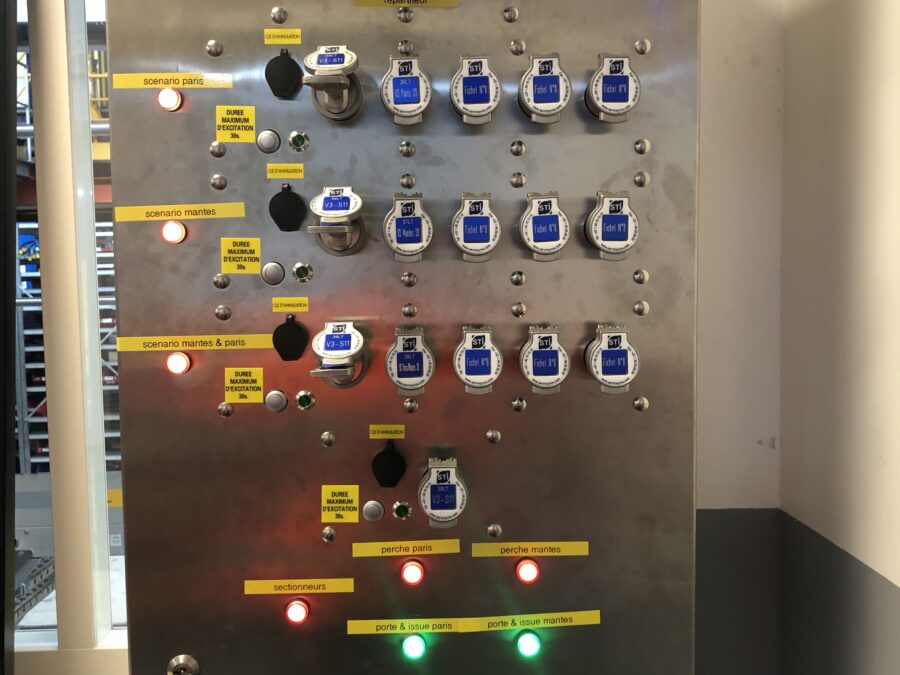

The Zonegreen EIS is an advanced safety system designed to protect personnel and equipment in high-risk environments. Using intelligent control panels and electronic sensors, it authorises the operation of multiple types of depot equipment and controls access to hazardous areas. By enforcing a predetermined sequence of events for every procedure, the system ensures that operations only proceed once all safety conditions have been met – for example it is only possible to access high level gantries when the catenary is isolated. This innovative approach significantly reduces risk, enhances operational efficiency, and delivers uncompromising safety standards for modern rail and industrial applications.

The benefits of Zonegreen EIS include:

- Flexible and Programmable – The software can be reprogrammed to accommodate different safety sequences.

- High Reliability – Zonegreen EIS uses fail-safe principles to ensure safety functions operate, even in the event of faults.

- Easier to Scale – The product can handle multiple interlocking zones without adding more physical locks and keys.

- Remote Diagnostics – Zonegreen EIS allows troubleshoots and status monitoring remotely.

- Fast Operation and Tamper Proof – The electronic system uses encrypted communication and authentication.

- Visualisation – Zonegreen EIS offers a remote visual overview of the system.

Zonegreen EIS is a configurable solution, designed to accommodate individual rail depot installations and their significant variations in operating procedure.